We P.G. Drive are Manufacturers, Exporters & Leading Suppliers Of Gearbox Repair & Gearbox Rebuild Services Located in Mumbai, India.

GEARBOX REPAIR, REBUILD & SPARES

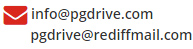

Leading German Brand Gearbox

Application: Twin Screw Extruder For Compounding

Our Contribution: Complete Gear Train Parts (Design Verfied & Manufactured By Us)

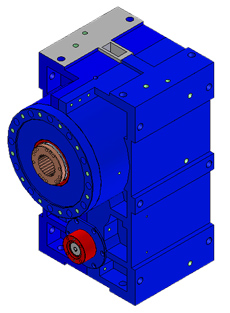

Leading Italian Brand Gearbox

Application: Twin Screw Extruder For Compounding

Our Contribution: Complete Gear Train Parts (Design Verified & Manufactured By Us) & Tandem Thrust Bearing Replacement

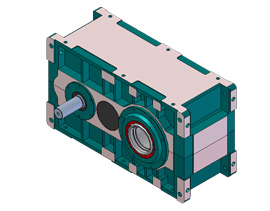

Leading German Brand Gearbox

Application: Twin Screw Extruder For Compounding

Our Contribution: Complete Gear Train Parts (Design Verified & Manufactured By Us)

Our Design

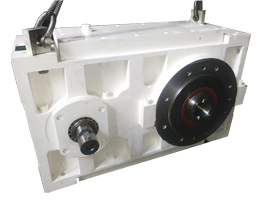

Leading German Brand Gearbox:

Application: Twin Screw Extruder For Compounding

Our Contribution: All Bearings, Damaged Spline Shafts, Tandem Thrust Bearing, Gearbox Servicing & Assembly

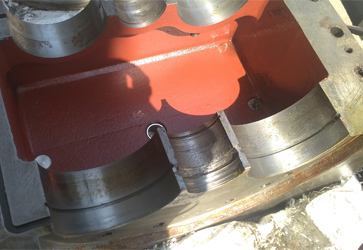

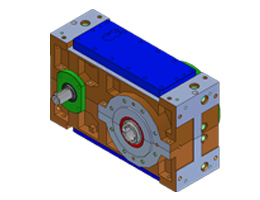

Leading Italian Brand Gearbox

Application: Twin Screw Extruder For Compounding

Our Contribution: Complete Gear Train Parts (Design Verified & Manufactured By Us) & Housing Salvaged

At P G DRIVE we are experts when it comes to rebuilding heavy industrial gearboxes. We don't just fix your problems; we use detailed analysis to find out why things went wrong in the first place. We also take into account increased operational demands. To learn more about our cost-effective and efficient gearbox rebuilding service, please see the details below. For information about the rest of our services, please contact P. G. DRIVE today.

Inspection

P G Drive utilizes modern state of the art inspection equipment, to inspect incoming gearbox components for reverse engineering and manufacturing purposes.

Repair

We have the manufacturing and engineering capacity to repair most gearbox designs. If a catastrophic failure occurred we can analyze the gearbox and identify all modes of failure, therefore we can provide the proper corrective action. All gearboxes have to undergo a no load test.

Reverse Engineering

We can recreate most damaged, broken, or obsolete case, gear, or component part. By facilitating these resources, we can reverse engineer and produce nearly any part or assembly, from a drop-in replacement to a complete rebuild of the gearbox.

Customers send their gearbox in for evaluation on the extent of the damage, and we help them make an educated decision as to whether they will do a repair, rebuild or purchase a new unit.

Considerations:

• Re-design or reverse engineering options to reduce design complexity

• Improved lead time with repair & direct drop in replacement

• Repair can be less expensive

P G DRIVE is currently assisting the END USER customers and DISTRIBUTORS in the replacement of gear drives of any brand.

We can repair and rebuild any make model gearbox from any manufacturer, including:

• Brevini

• PIV

• Falk

• Demag

• Lenze

• Hyosung

• Flender

• Kissling

• Barmag

• Fairfield

• Cleveland

• Cone

• Lufk

• Rollstar

• Rossi

• Hall

• SEW

• Sumitomo

• Zambello

• David Brown

• Elecon

• Greaves

• Radicon

• Premium transmission

• Shanthi

BENEFITS OF GEAR BOX REPAIRS AND REBUILDS:

• Offers a cost-effective alternative to new equipment

• Results in shorter lead times than new equipment

• Allows for plant personnel to be utilized for other tasks

• Enables upgrades to be incorporated into the rebuild

• Helps to ensure equipment reliability

• Provides a proactive way to maintain equipment

Our team can perform reverse engineering during gear box repairs and rebuilds, which enables us to supply all of the necessary parts in the future.

Reverse Engineering

If in some cases the client does not have the technical data of the gearbox to be overhauled. We therefore use reverse engineering to "copy" the existing parts to be replaced. This means that these new parts at least comply with the specifications of the original parts.

DROP IN GEARBOXES EXAMPLES

Leading German Brand Gearbox

Application: Cutter Feeder Gearbox For Recyling Extruder.

Customer Required Design

Our Product Design

Our Product Delivery

A Leading Italian Brand Gearbox:

Application: Main Extruder Screw Gearbox For Recyling Extruder

Customer Required Design

Our Product Design

Our Product Delivery

Leading German Brand Gearbox:

Application: Blown Film Extrusion Plant

Customer Required Design

Our Product Design

Our Product Delivery

Leading german brand gearbox:

Application: 35 tons crane main winch drive gearbox

Customer Required Design

Our Product Delivery

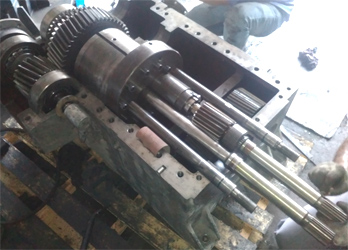

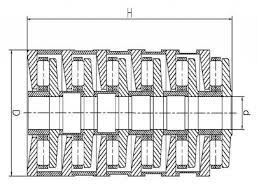

TANDEM THRUST BEARING: (Tandem Thrust Cylindrical Roller Bearing)

At P G DRIVE, we are experts at servicing your critical twin screw extruder gearboxes and we also have contact with worldwide best suppliers for the supply of most critical tandem thrust bearing used in your twin screw gearboxes. We do have few in stock which we keep it for our regular customers. Please send us your requirement to help you source the right quality bearing for your critical twin screw gearbox.

Tandem Thrust Bearings can receive heavy load in a limited space and support firmly in the direction of axis and last long with low frictional power. In addition, these bearings are moved by oil lubrication. Also these tandem thrust bearings are used principally in gear boxes for single & twin screw extruders in the rubber and plastic industries

HIGH PRESSURE PUMP FOR GEARBOX OPENING, TWIN SCREW SPLINE TIMING AND BEARING REPLACEMENT:

P G DRIVE has the equipment and expertise of opening of critical gearbox, setting spline timing for twin screw gearbox with the use of High-Pressure Pump (Maximator, Riken Seiki. Huskel, Oilmat etc)

Certain gearboxes and bearings require High Pressure pump for opening and closing the gearbox housing.

Certain Twin screw gearboxes require high pressure connection to set the spline timing in the gearbox which then requires these kinds of pumps.

We provide the high-pressure pump and required expertise to service such gearboxes.